Industry 4.0

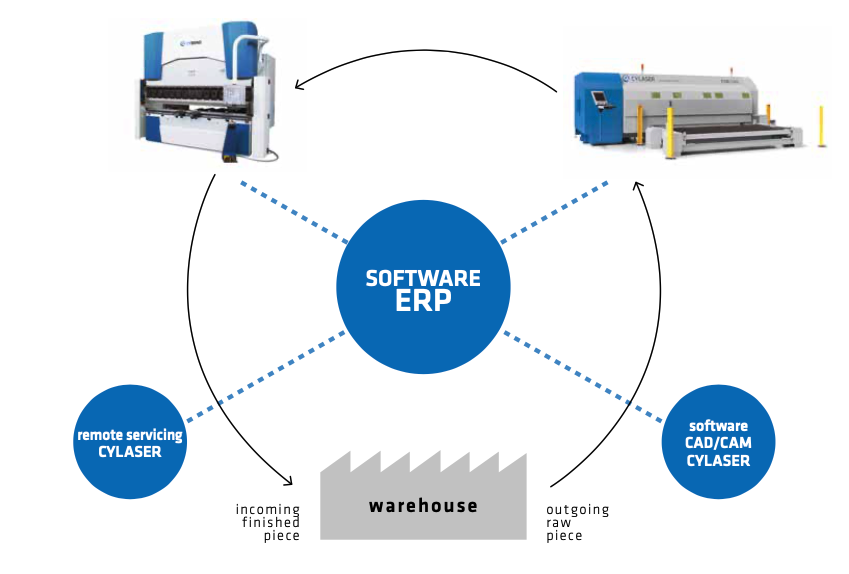

The CYLASER cyber-physical system can be integrated seamlessly

with other machinery of the production cycle thanks to the CYLASER Open Source software

which is able to manage any existing automation system. It automatically fits into a company’s logistic system.

Remote and self-diagnosis software applications allow remote control and assistance.

The CYLASER 4.0 innovation improves:

- versatility through the production of small batches at large-scale costs;

- fast development from the prototype to mass production;

- productivity through shorter set-up time, less errors and machine downtime,

- quality through sensors that monitor production in real time reducing production scraps.

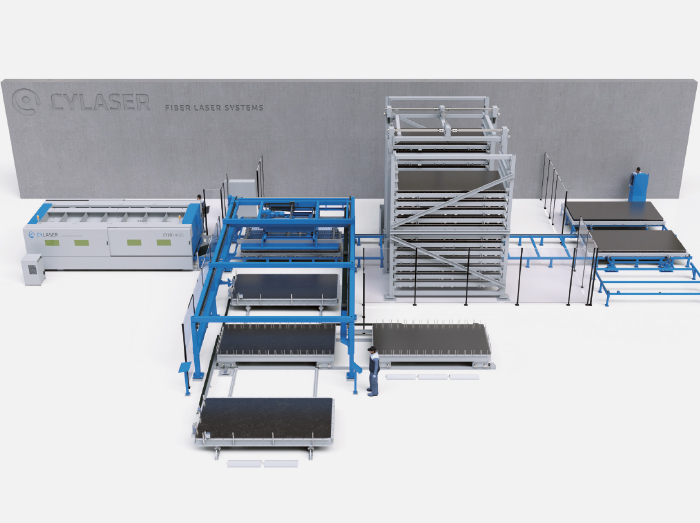

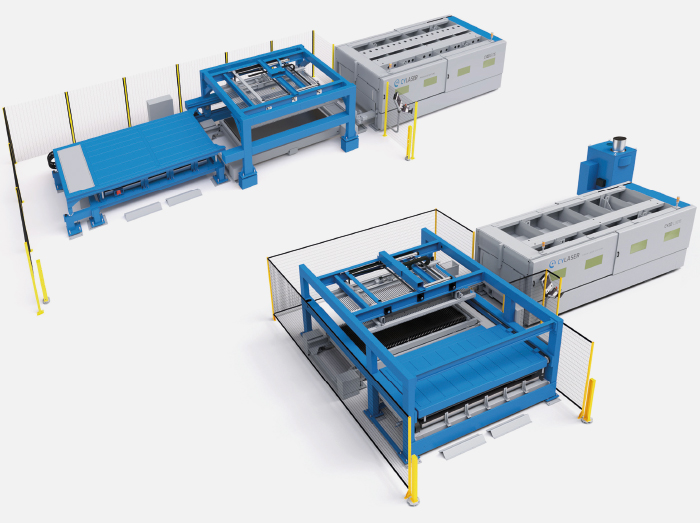

Automated Production

CYLASER systems can be integrated with different types of automation,

from the loading/unloading server to the automated storage tower

for completely unmanned production. The CYLASER software allows the integrated management

of third-party integration systems thanks to the open source concept.

![]()

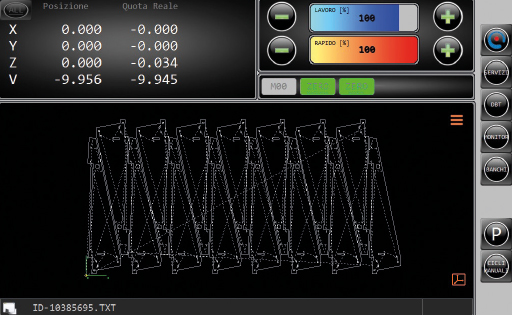

Automation Taylor-made software

Simple and user-friendly

interface:

- Easy-to-use and customizable graphic system;

- Features all the software needed for management

on the machine and remotely; - Possibility to choose a normal PC

as a more flexible and affordable alternative. - Possibility to integrate a hand-held device

per il controllo della macchina

o control the machine from any position.

FEATURES

- Certified for the main CAD-CAM software on the market,

for the maximum degree of integration with any existing system; - It fits perfectly into the company network

to ensure remote servicing and diagnostics; - It allows sharing the cutting technologies

with management and quotation systems;

CYLaser 4.0

Automatic evolution