CY-FAST MARK

CY-FAST MARK

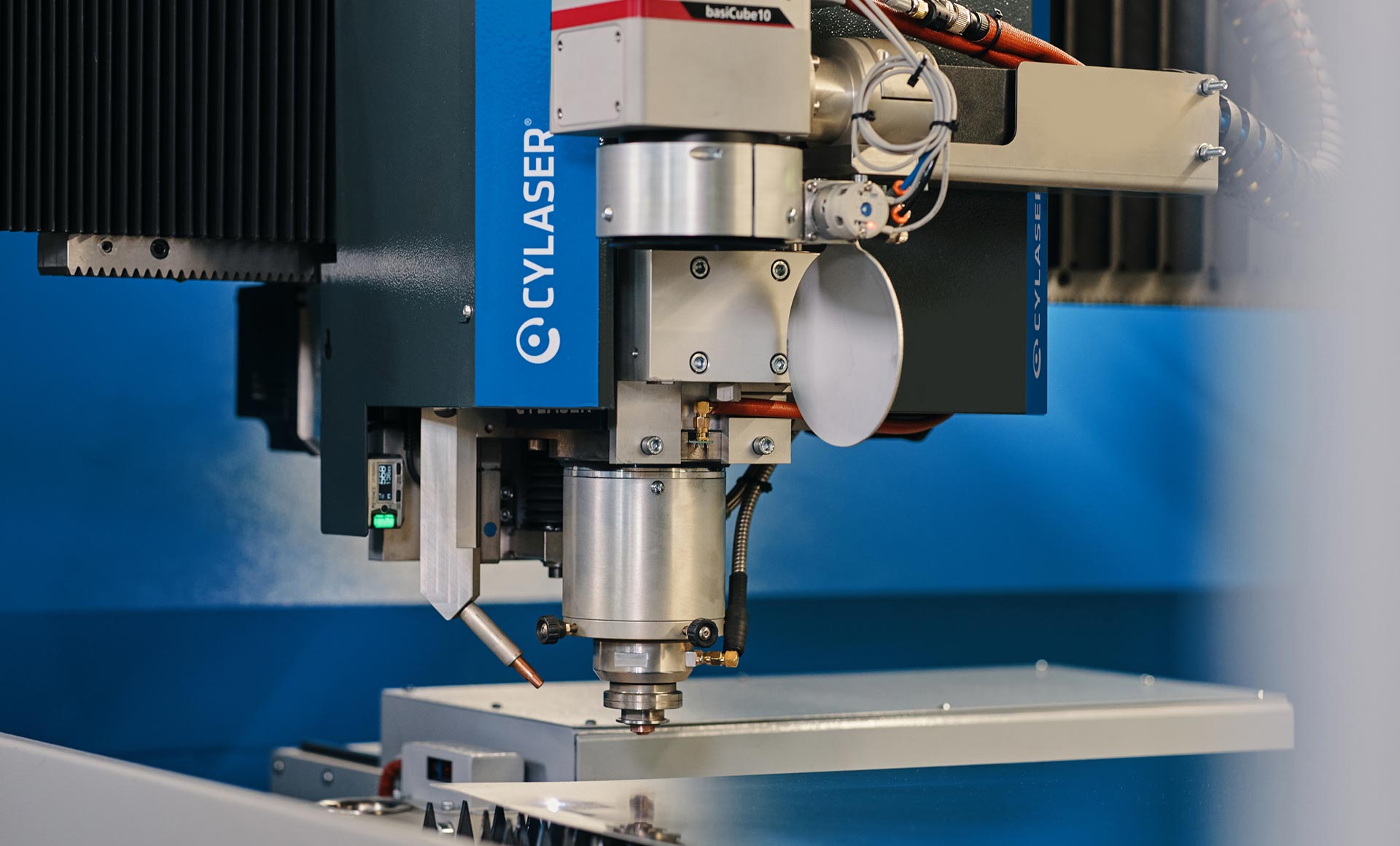

The new Cy-laser

galvo marking head

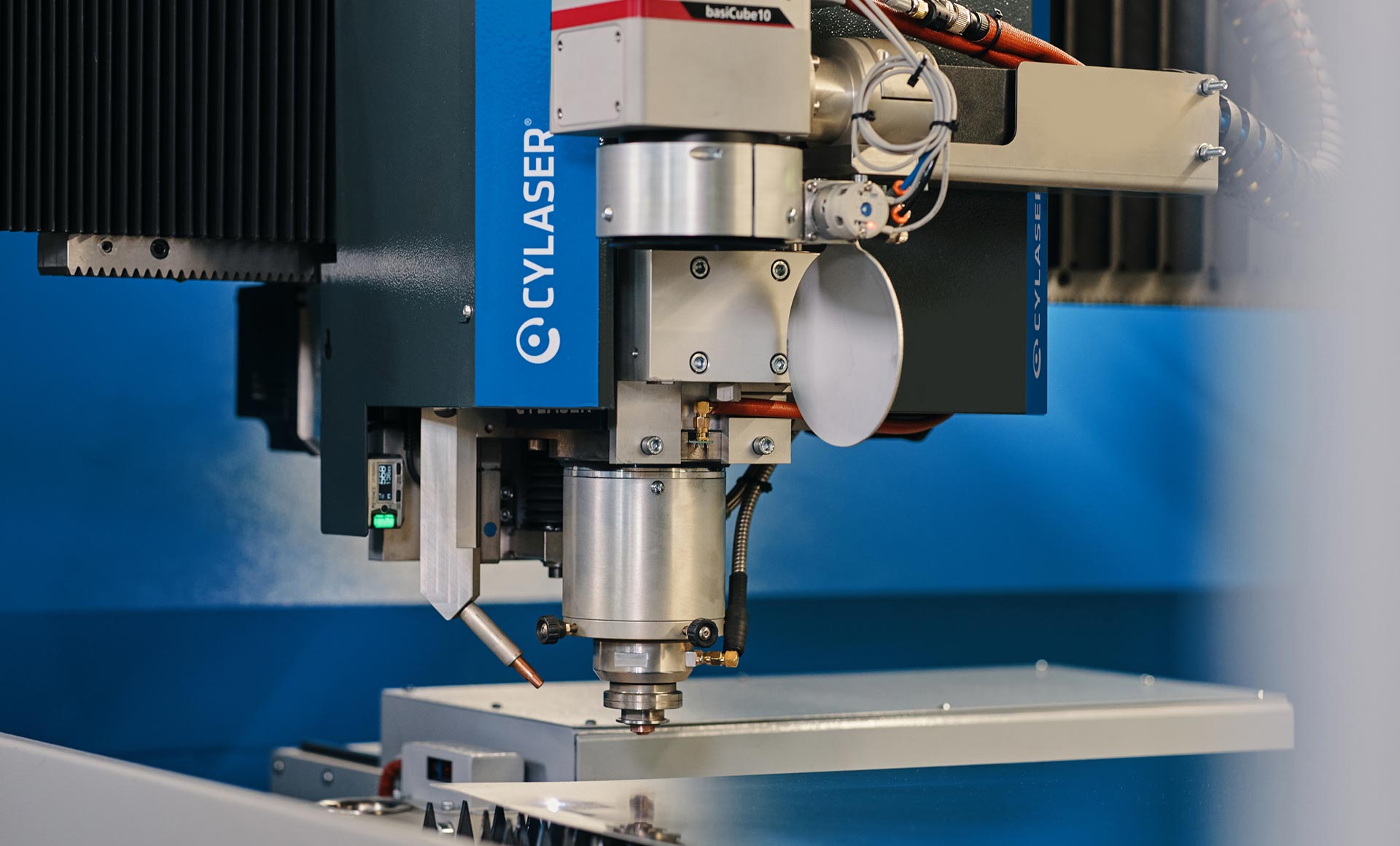

Since its founding in 2005, Cy-laser has pioneered the practical application of fiber laser sources.

Today Cy-laser presents the CY-FAST MARK.

The Cy-laser continuous evolution.

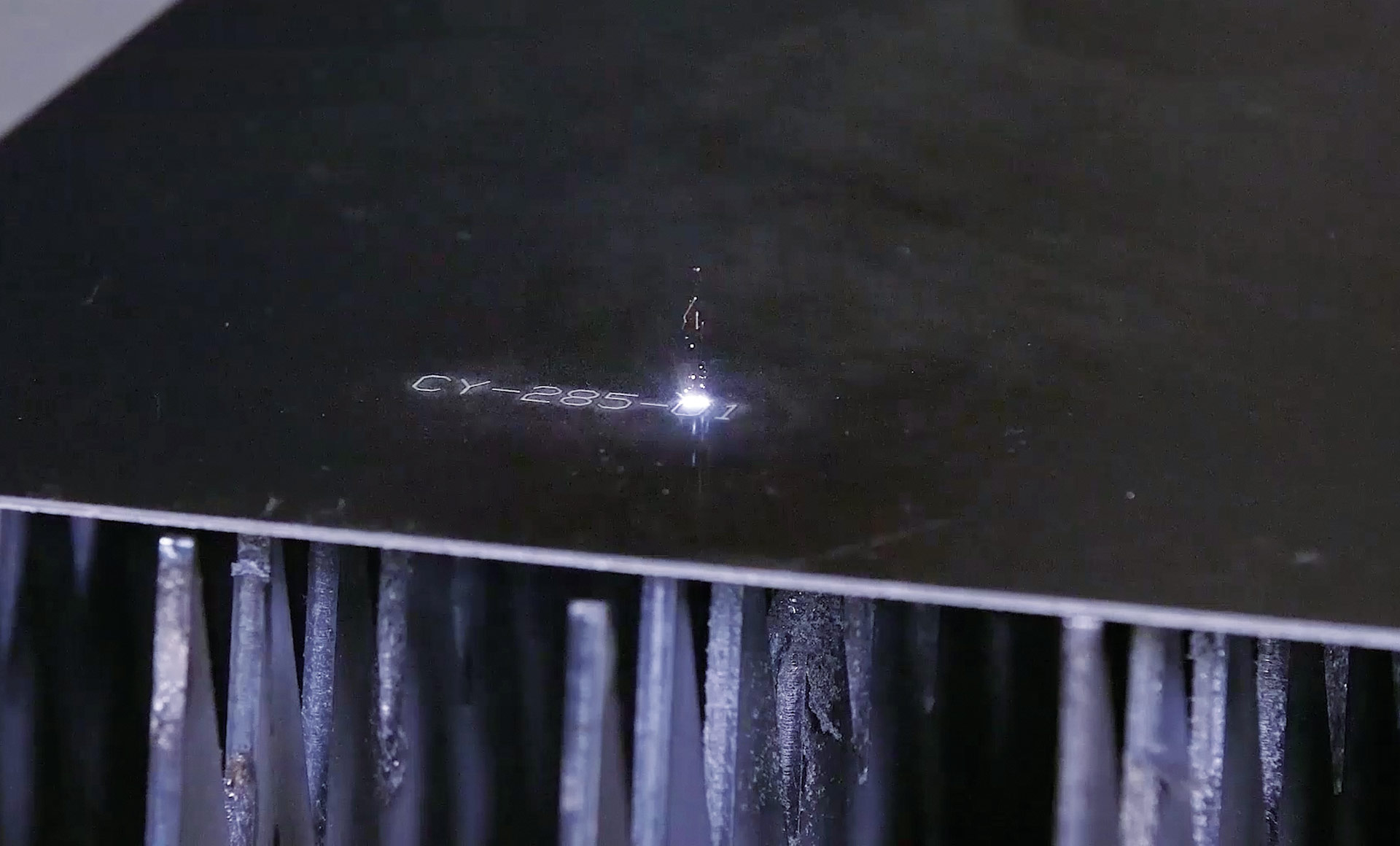

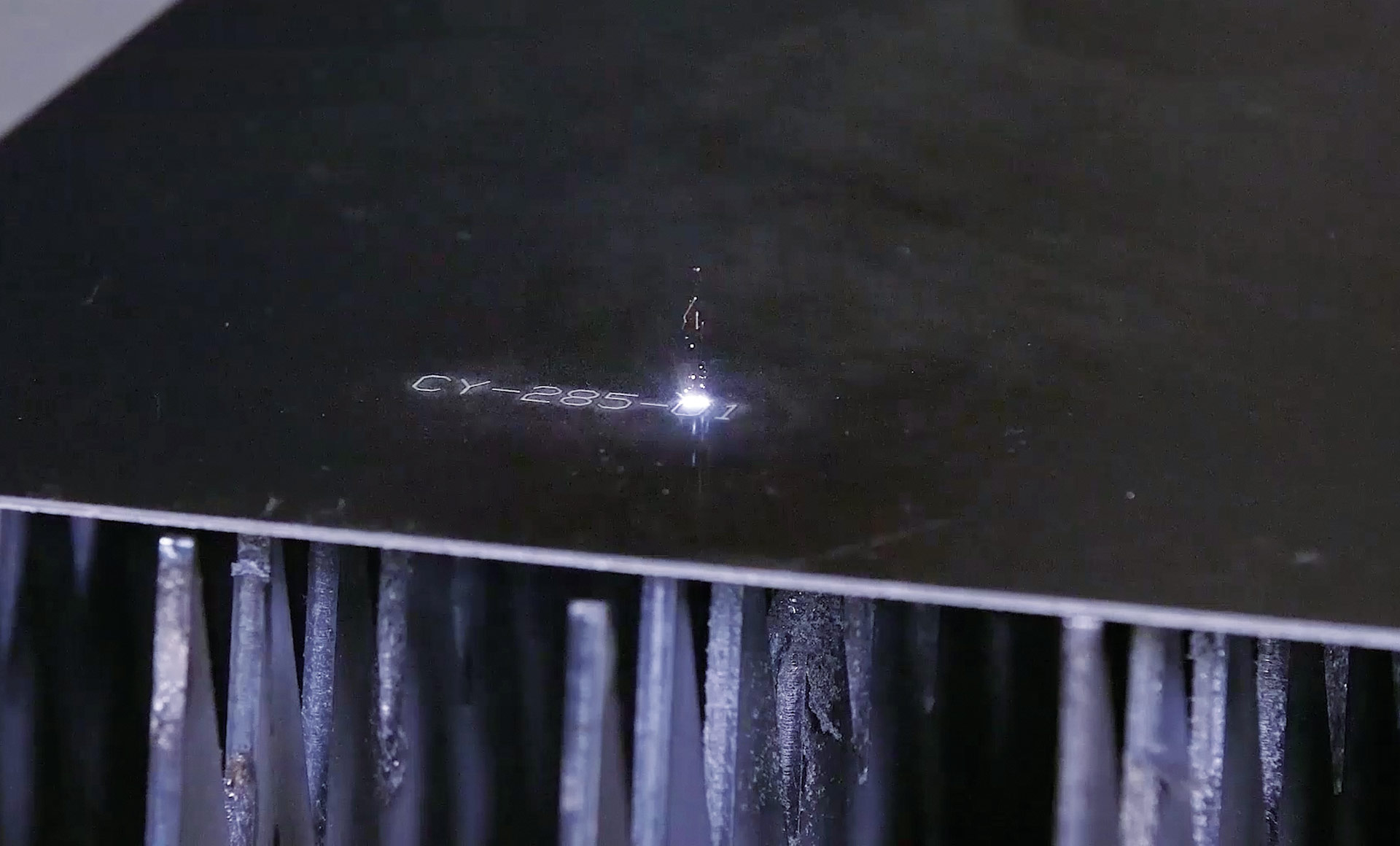

PARTS ARE NOT ALL THE SAME

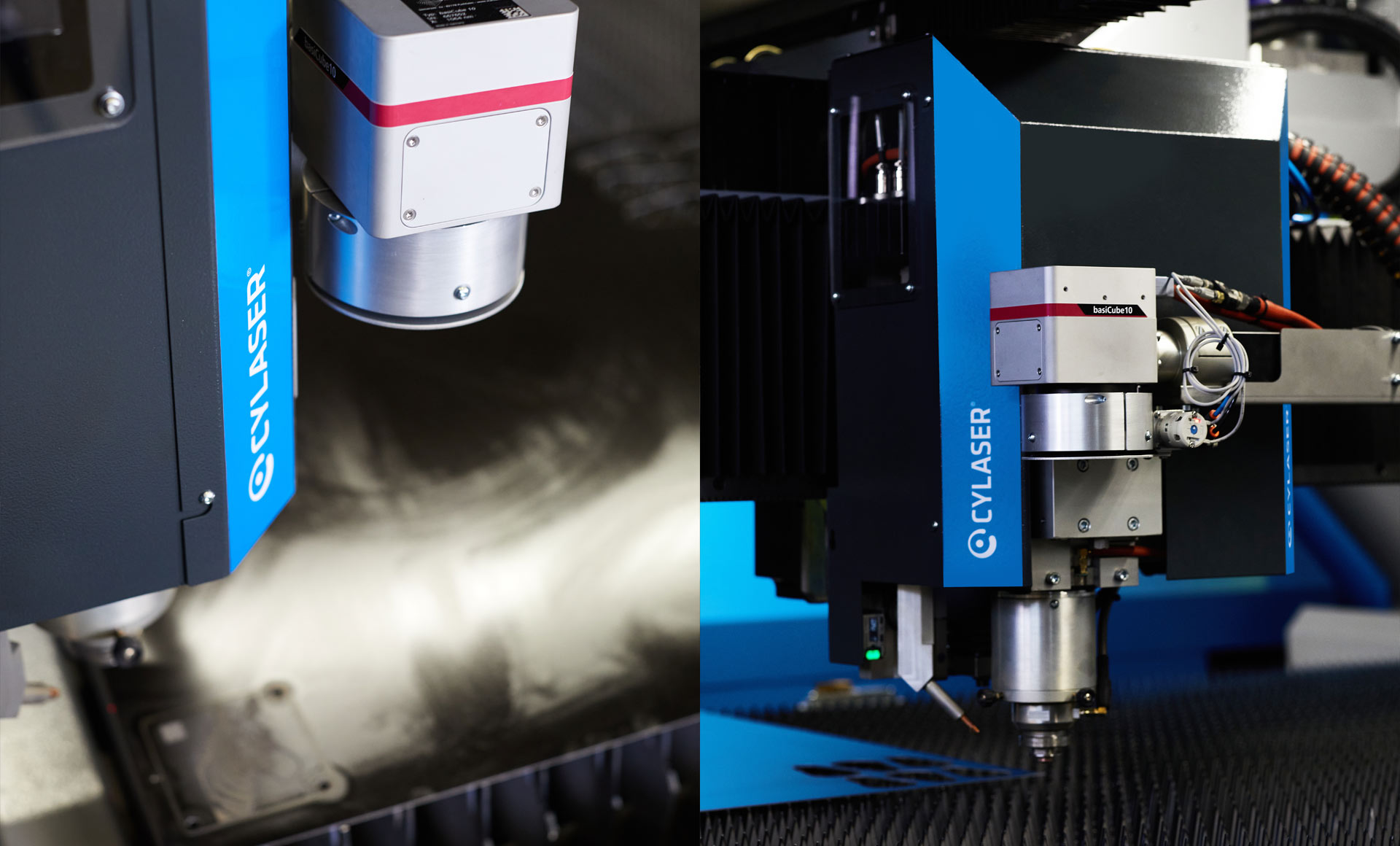

The installation of the galvo marking head CY-FAST MARK, with customized marking levels and the possibility to mark film coated materials,

allows a very high-speed marking execution and a 40% time saving compared to traditional machines.

As part tracking has become fundamental for subcontractors, this device represents

definitely an added value to offer to their customers and it fits perfectly into the “Industry 4.0” context.

MARKING AREA

The galvo marking head has a limited working area that depends on the type of focus lens installed.

More specifically:

- Area 80x80mm (support in position 1 – Gantry LM Structure)

- Area 112x112mm (support in position 1 – Aeroplane Structure)

- Area 174x174mm (support in position 2 – Aeroplane Structure)

CAD/CAM

Grazie al CYCAMLAB sarà possibile gestire:

- La marcatura a zone. Nello specifico tutte le marcature incluse in una zona,

le cui dimensioni sono date dall’area di lavoro della testa, potranno essere

raggruppate ed eseguite senza ulteriori movimentazioni della testa - La sequenza zone

- La gestione dei parametri di marcature

(4 penne standard o la possibilità di personalizzarle in base alle necessità)

CY-FAST MARK: SOFTWARE

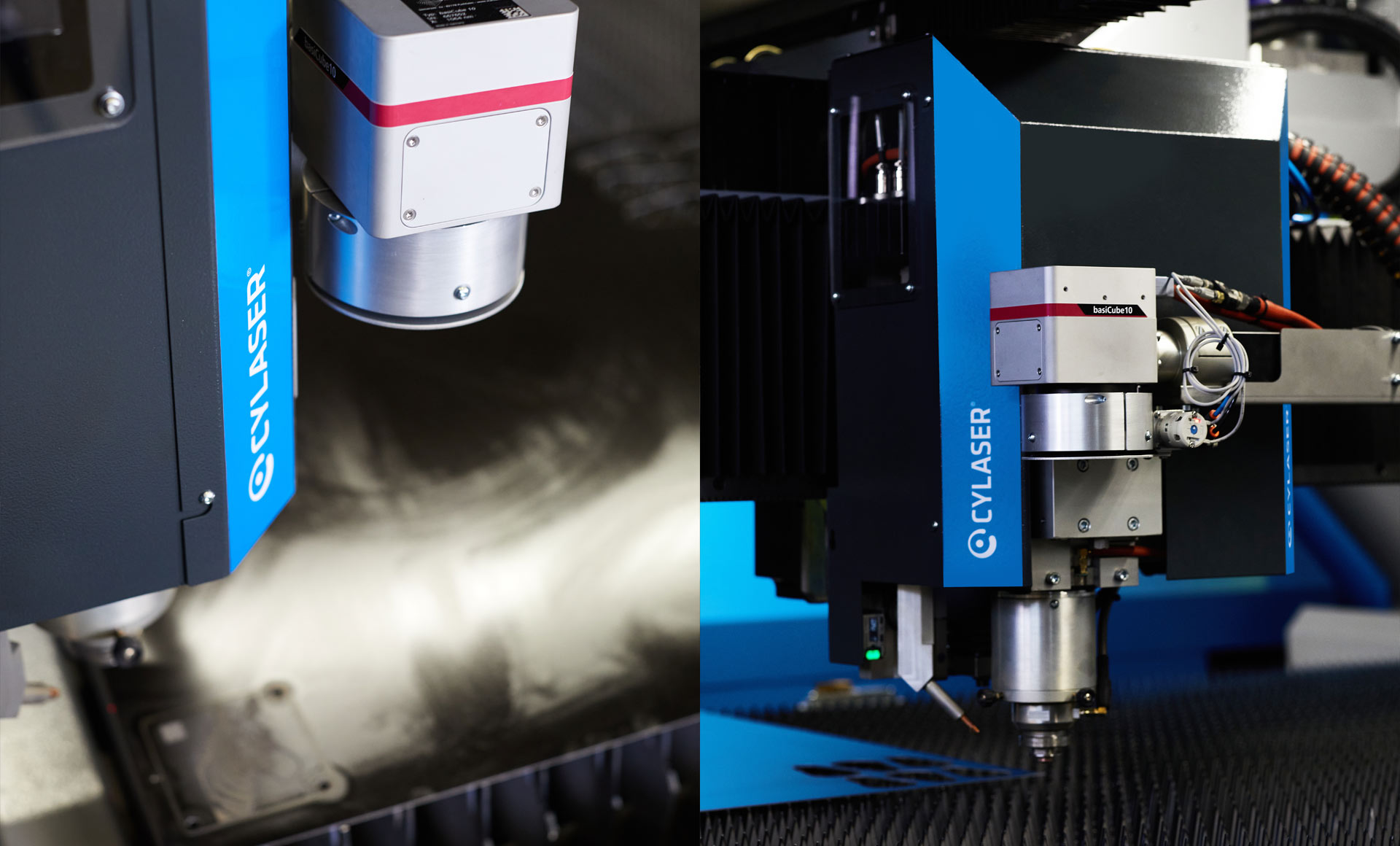

Cy-laser developed this software to pilot its laser marker separated from the cutting laser source but coordinated in its movements during post-processing. The CAM generates a second post-processor specifically for markings. The “marking service”, carried out by the CNC PC, loads the path in the marking card. The “communication drivers” synchronise the information between the marking service, the CNC and the marking controller card during post-processing.

The management is structured to function with both the CNCs (ESA and ECS). The marking service is a programme with no user interface that synchronizes the marking operations with the execution of the cutting post-processor, stores the marking part program, roto-translates it according to sheet orientation, and uploads it into the marker card. The low-level communication operations are requested to the drivers. For each of the two CNCs there is a driver that exchanges data via the libraries that manufacturers make available. The following data are exchanged:

- The name and the path of the existing post-processor (from which the name of the marking post-processor can be found)

- The orientation of the sheet metal

- The identification of the mark to be made

- The consent to load the mark into the card

- The loading of the mark into the card

MARKING AREA

The galvo marking head has a limited working area that depends on the type of focus lens installed.

More specifically:

- Area 80x80mm (support in position 1 – Gantry LM Structure)

- Area 112x112mm (support in position 1 – Aeroplane Structure)

- Area 174x174mm (support in position 2 – Aeroplane Structure)

CAD/CAM

Grazie al CYCAMLAB sarà possibile gestire:

- La marcatura a zone. Nello specifico tutte le marcature incluse in una zona,

le cui dimensioni sono date dall’area di lavoro della testa, potranno essere

raggruppate ed eseguite senza ulteriori movimentazioni della testa - La sequenza zone

- La gestione dei parametri di marcature

(4 penne standard o la possibilità di personalizzarle in base alle necessità)

CY-FAST MARK: SOFTWARE

Cy-laser developed this software to pilot its laser marker separated from the cutting laser source but coordinated in its movements during post-processing. The CAM generates a second post-processor specifically for markings. The “marking service”, carried out by the CNC PC, loads the path in the marking card. The “communication drivers” synchronise the information between the marking service, the CNC and the marking controller card during post-processing.

The management is structured to function with both the CNCs (ESA and ECS). The marking service is a programme with no user interface that synchronizes the marking operations with the execution of the cutting post-processor, stores the marking part program, roto-translates it according to sheet orientation, and uploads it into the marker card. The low-level communication operations are requested to the drivers. For each of the two CNCs there is a driver that exchanges data via the libraries that manufacturers make available. The following data are exchanged:

- The name and the path of the existing post-processor (from which the name of the marking post-processor can be found)

- The orientation of the sheet metal

- The identification of the mark to be made

- The consent to load the mark into the card

- The loading of the mark into the card