Bevel

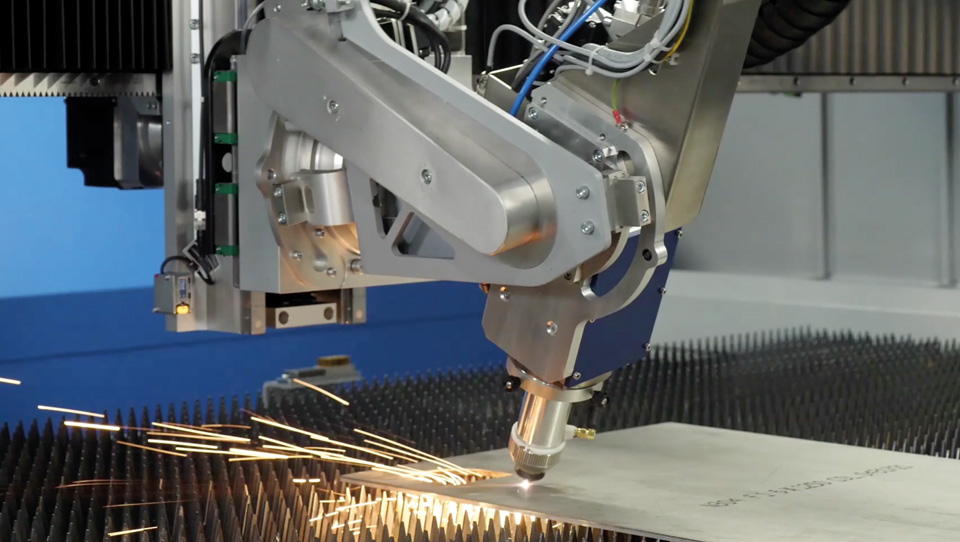

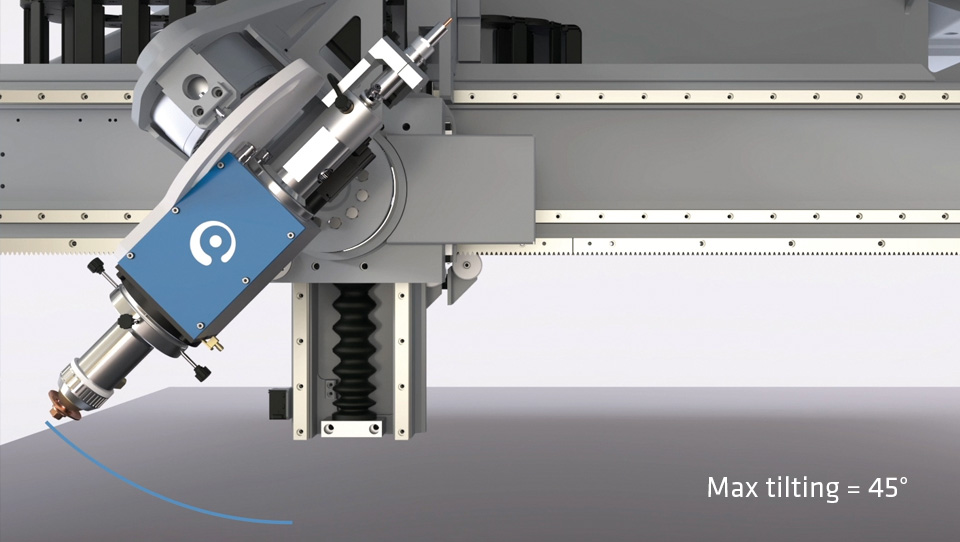

Bevel is a process option to obtain bevelled cuts (up to 45°).

It is usually adopted to increase the surface area of the edge for a stronger and consistent welding.

There are different types of bevelled edges which are indicated by the letter of the alphabet that mostly resembles the shape of the cut when seen in cross-section. The most common types of bevelled cuts include V, A, X, Y upwards, Y downward and K. Although it is possible to cut a bevelled edge using a manual cutting tool, bevel edges are often cut using a torch, a specific cutting head mounted on a CNC cutting table or on a beam processing machine. In the past, the bevelled edges required several trials due to the high number of existing bevelled cuts. The new technologies, such as fiber laser, have improved remarkably speed, repeatability and precision of the bevel cuts thanks to the inclusion of common parameters in the software used to control the movement of the cutting head or the laser head for bevel cutting. Cy-Laser software allows to create bevelled pieces or to import them automatically from the CAD.

Trends in bevelled edges:

- Bevelled edges are necessary for the preparation of welding and other final assembly methods

- The need to increase productivity along with constantly labour cost increase as well as the decrease of skilled workers, are pushing companies to adopt automated technologies for bevel cutting.

Automated technologies ensure improved accuracy and repeatability aimed at an increasing productivity.